With a new Raleigh Motovilla awning, my home made full length roof rack and some renewed confidence in our VW since covering some significant miles around the UK we decided to take our bus over to France. Now for some this isn't a big issue, maybe living in London, but as we're in Newcastle we've got an 8hr drive just to get to Dover with maybe another half a days driving in France to get over to Brittany. We drove over 1500 miles in two weeks without a hitch.

Front spot in ferry queue

Etables Sur Mer - AbriCotier campsite is excellent

Warm nights at AbriCotier

Boy engrossed in TV inside the Holdsworth

At Le Brevedent

Finally the best campsite we've ever found in France, http://www.camping-lecolombier.com/en/

Double bed out, we've installed a rock and roll bed within the existing Holdsworth seat base.

The fold out single bed, formally made part of the double, now functions as a useful single for our small boy

The story of our VW T2 Holdsworth

Wednesday, 4 June 2014

Sunday, 14 April 2013

On the floor

The ride height has bugged me from the start. I didn't like the way the bus drove or the way that it looked so the lowering time had come. The front wasn't easy though and took a while to get the height properly dialled. The back was very easy :0).

The front beam was removed to allow me to fully assess the chassis above it which was in remarkably good shape. As well as fitting the adjusters I also rebuilt the calipers, fitted a new steering damper, removed the bump stop mounts and did loads of other front beam related stuff....

The front beam was removed to allow me to fully assess the chassis above it which was in remarkably good shape. As well as fitting the adjusters I also rebuilt the calipers, fitted a new steering damper, removed the bump stop mounts and did loads of other front beam related stuff....

The Engine Rebuild

It was a lovely sunny day and we were heading back from the lakes and the camper was getting slower and slower and then.........bang. The engine overheated and one of the pistons seized in the barrel, the connecting rod kept going causing a right mess.

So, it was decided to throw even more money at the bus and try to guarantee some reliability (although this is impossible) by buying a brand new engine from VW Mexico. This came via VW Heritage in the UK and has been a very good strong engine though not without some push-rod tube issues causing a few teething troubles. The block as delivered was built up with pretty much ALL new ancillaries total engine build cost circa £3k!

So, it was decided to throw even more money at the bus and try to guarantee some reliability (although this is impossible) by buying a brand new engine from VW Mexico. This came via VW Heritage in the UK and has been a very good strong engine though not without some push-rod tube issues causing a few teething troubles. The block as delivered was built up with pretty much ALL new ancillaries total engine build cost circa £3k!

All back together

It took some months to finish off the paint and with the looming excitement of a trip to the lakes we put our bus back together as quickly as we could - we didn't cut any corners but we didn't do all of the things we wanted to (like new front seat covers).

So, all new rubbers, powder coated bumpers, painted wheels silver, new chrome hub caps, classic number plates, light lenses, aerial, painted dash, rear carpet, brown cord curtains, reupholstered seats, new cooker and fabricated sink (thanks dad) plus loads (and i mean loads) of other stuff.

So, all new rubbers, powder coated bumpers, painted wheels silver, new chrome hub caps, classic number plates, light lenses, aerial, painted dash, rear carpet, brown cord curtains, reupholstered seats, new cooker and fabricated sink (thanks dad) plus loads (and i mean loads) of other stuff.

Monday, 11 February 2013

Prep and paint

With the metalwork finished we moved onto painting the bus. I found it difficult to find anyone willing to paint the bus for a reasonable price so I decided to paint it myself ..... with a roller. Now this may seem to most people madness, however old Rolls Royce vehicles were hand painted so why shouldn't my bus.

I painted the bus with Rustoleum CombiColour RAL2000 Orange and RAL 9000 White. The first stage involved rubbing the whole bus down with 120 grit. After two coats with the roller I then wet sanded with 400 grit, then another two coats, then wet sanded with 800 grit then another two coats then 1000 grit then a machine polish with G3.

I have to say that I was impressed with the end shine and depth of paint, the negatives would be that the paint is very hard and chips easily often taking a 1p sized chunk with it especially on the front panel.

I painted the bus with Rustoleum CombiColour RAL2000 Orange and RAL 9000 White. The first stage involved rubbing the whole bus down with 120 grit. After two coats with the roller I then wet sanded with 400 grit, then another two coats, then wet sanded with 800 grit then another two coats then 1000 grit then a machine polish with G3.

I have to say that I was impressed with the end shine and depth of paint, the negatives would be that the paint is very hard and chips easily often taking a 1p sized chunk with it especially on the front panel.

The metalwork

I'm luckier than most VW fanatics in the my father is a sheet metal worker, that's to say that he's good to have around when cutting, forming and welding panels and chassis parts to go onto the bus. The bus needed welding in all of the usual areas, basically the bottom 6" of panels all around the bus and a new section of chassis leg around the engine, some floor work and a couple of outriggers too.

We tried to keep as much of the original VW metalwork as possible and only replaced what was absolutely necessary.

The rear apron / valance was rotten so this was replaced fully.

A small repair made to the front bumper deformation panel.

Both of the rear corner needed replacing...

surprisingly the battery tray on the ns was ok

a new rh chassis leg was fabricated by dad complete with captive nuts internal to the box section for the bumper irons.

Both doors needed some bottom repairs, both new repair panels were fabricated by dad...

Both steps and front arches had thankfully been replaced but the small closing section was needed on the os.

Additional to this there were a number of patches to the floor required, the roof corner needed replacing along with some gutter sections.

We tried to keep as much of the original VW metalwork as possible and only replaced what was absolutely necessary.

The rear apron / valance was rotten so this was replaced fully.

A small repair made to the front bumper deformation panel.

Both of the rear corner needed replacing...

surprisingly the battery tray on the ns was ok

a new rh chassis leg was fabricated by dad complete with captive nuts internal to the box section for the bumper irons.

Both doors needed some bottom repairs, both new repair panels were fabricated by dad...

Both steps and front arches had thankfully been replaced but the small closing section was needed on the os.

Additional to this there were a number of patches to the floor required, the roof corner needed replacing along with some gutter sections.

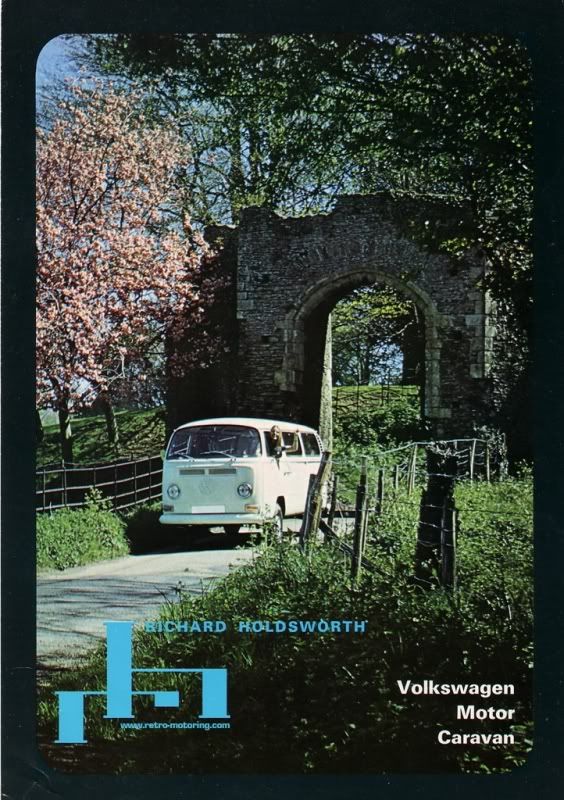

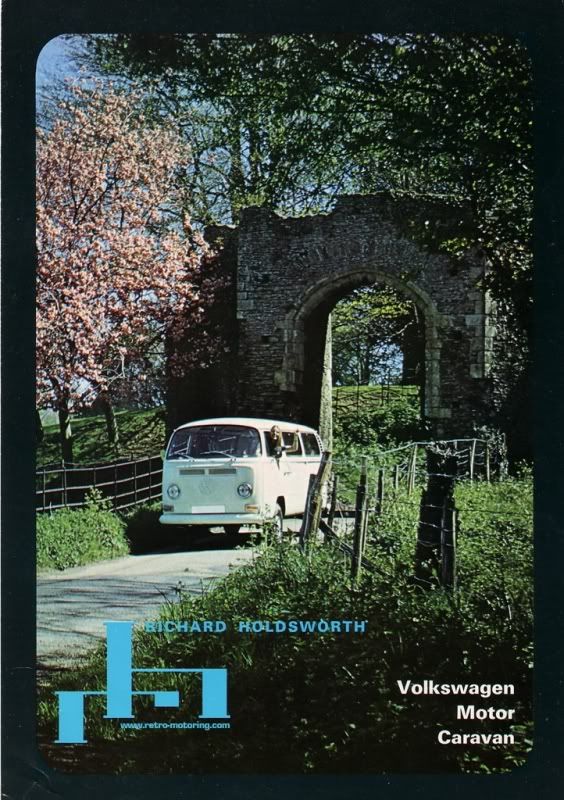

A piece of VW history....

Well, we didn't know it at the time but our little VW is in a very small way a piece of VW history. It's not the most sort after conversion, nor is it the most practical, however original VW T2 Holdsworths are becoming very rare with one estimate I heard of less than ten examples left!

I'm guessing that these are rare because the Holdsworth T2 conversion was cheaper than most other conversions and it also was made from a panel van, meaning the windows are cut into the metalwork rather than the window surrounds being formed at VWs Wolfsburg factory in Germany, this makes them generally less desirable.

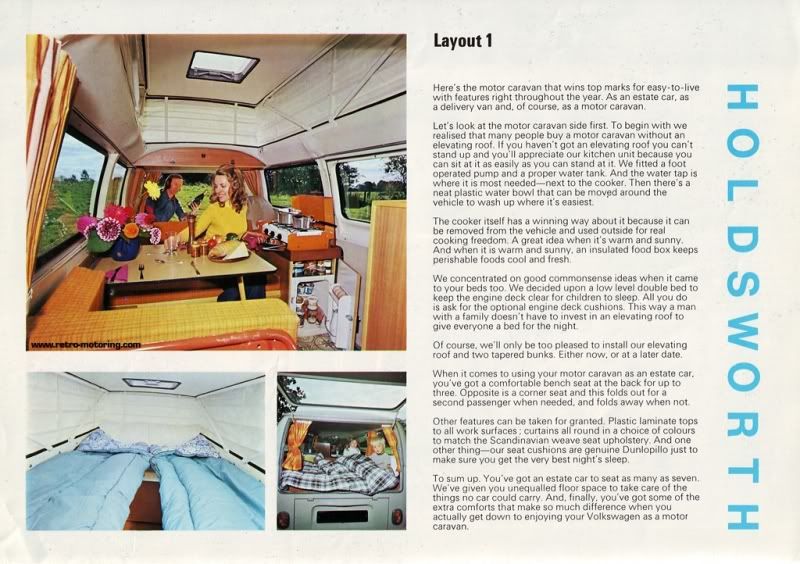

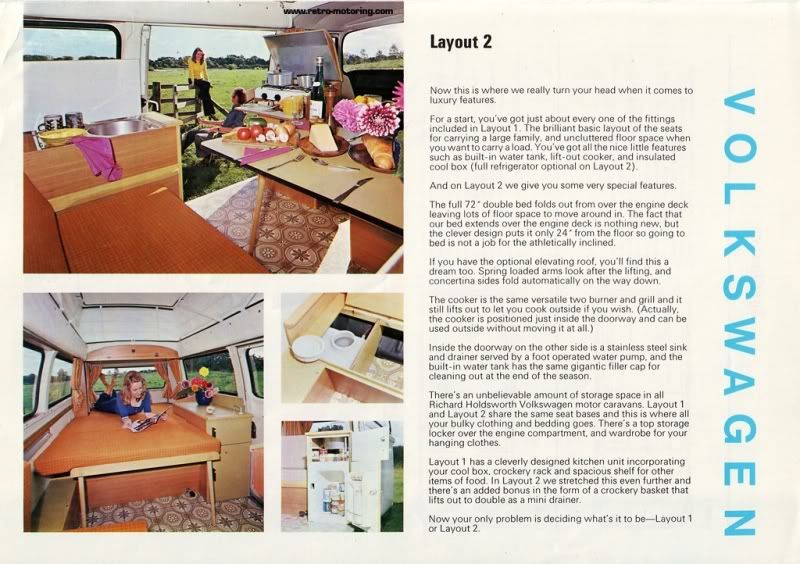

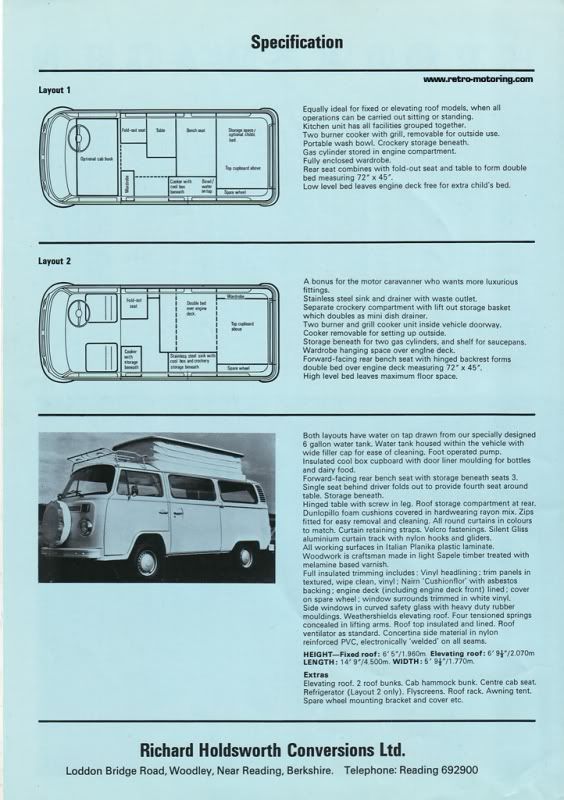

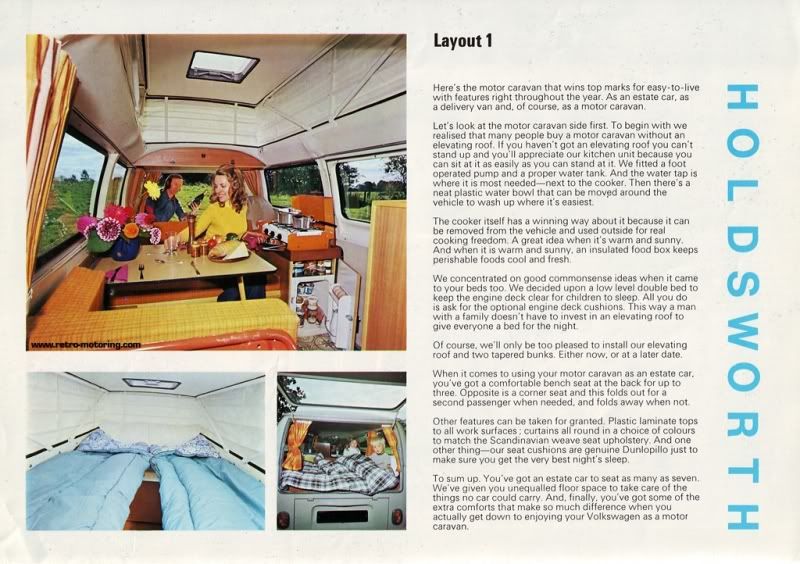

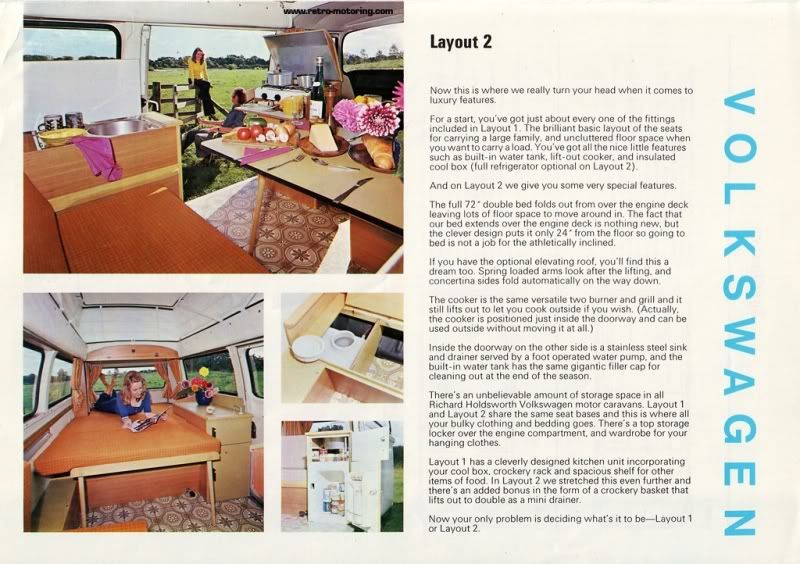

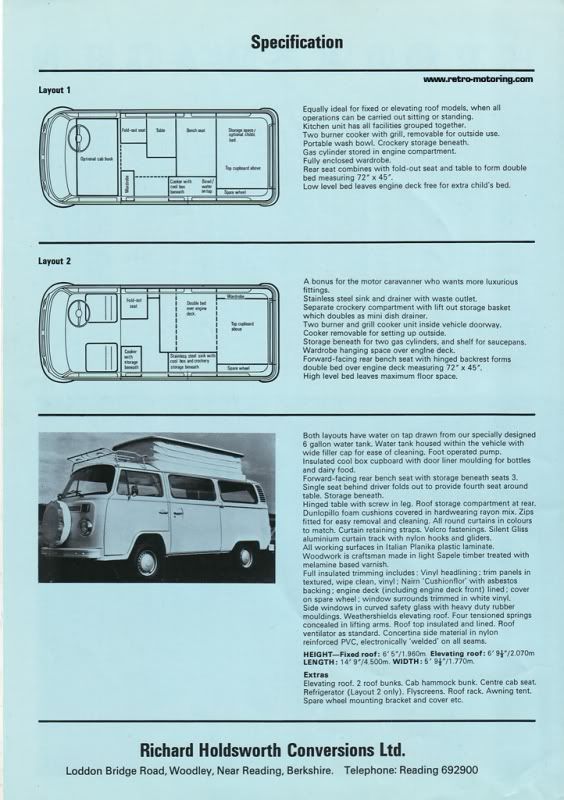

I did find some copies of an original T2 Holdsworth brochure...

Our interior is basically Layout 1 without the poptop and without the fridge. It does have a storage hole at the far side of the cooker which can't be seen in the above photo.

When we received the bus the interior was just thrown in the back, there were some hideous green curtains and the original seats cushions were totally threadbare and beyond repair. Importantly it was complete which makes restoring the bus to its original specification a much easier task.

I'm guessing that these are rare because the Holdsworth T2 conversion was cheaper than most other conversions and it also was made from a panel van, meaning the windows are cut into the metalwork rather than the window surrounds being formed at VWs Wolfsburg factory in Germany, this makes them generally less desirable.

I did find some copies of an original T2 Holdsworth brochure...

Our interior is basically Layout 1 without the poptop and without the fridge. It does have a storage hole at the far side of the cooker which can't be seen in the above photo.

When we received the bus the interior was just thrown in the back, there were some hideous green curtains and the original seats cushions were totally threadbare and beyond repair. Importantly it was complete which makes restoring the bus to its original specification a much easier task.

Subscribe to:

Posts (Atom)